What is sustainable living? How Your Choices Shape a Sustainable Present and Future

By embracing sustainable living, we adopt practices that contribute to the well-being of the environment, society, and economy.

What are the different types of plastic that can be recycled?

What does the "100% recyclable" label on plastic products mean?

How can consumers make informed choices to support effective plastic recycling?

Within this post, we will explore the following:

- How much of plastic waste is recycled?

- Common Polymers in Recycling

- Plastic Resin Codes

- Plastic recycling process

We are all increasingly aware of the negative impact of plastic waste on our environment. Single-use plastics, in particular, have become a significant source of pollution, filling our landfills and oceans with non-biodegradable materials that harm marine life and ecosystems. Plastic pollution harms biodiversity, disrupts food chains, and contributes to environmental degradation.

Photo by Jonathan Chng on Unsplash

Photo by Jonathan Chng on Unsplash

Moreover, the production and disposal of plastic products generate greenhouse gas emissions, worsening climate change. As awareness of these issues grows, there is an agreement on the urgent need to reduce our reliance on plastics and adopt more sustainable alternatives to protect our planet for future generations.

Although we are aware that we urgently need to stop our plastic dependence since the news is out there:

The production of plastic waste is increasing. In 2017, on a global scale, we generated 348 million tonnes of plastic waste. Furthermore, by 2050, these numbers will be four times higher (1).

Around the globe, an estimated 8 million metric tons of plastic waste find their way into the oceans annually. Many countries generate substantial amounts of plastic waste that require proper disposal through effective waste management systems. The rapid accumulation of plastic waste in wastewater systems is an environmental challenge (2).

Please consider these numbers the next time you use a non-reusable water bottle or coffee cup.

Studies reveal that landfills currently contain 79% of the world's 6,300 million tonnes of plastic waste (3). Only 2% of the plastic packaging material accumulated over the past four decades has been recycled (4, 5).

Due to their durability, approximately 25 million tonnes of plastic accumulate in the environment each year (6). This persistent accumulation of plastic waste in dumpsites poses significant health risks to humans and animals.

Photo by Naja Bertolt Jensen on Unsplash

Photo by Naja Bertolt Jensen on Unsplash

Plastic waste generally follows three main pathways.

First, it can be recycled or reprocessed into secondary materials, which only delays final disposal and may not reduce future plastic waste unless it displaces primary plastic production (7).

The crucial information about plastic recycling is this: Recycled plastics are blended with virgin material to enhance their usability; however, they typically can only undergo recycling two or three times before their quality deteriorates to a point where they are no longer suitable for further use.

Second, plastics can be thermally destroyed, primarily through incineration, with or without energy recovery. Waste incineration harms the environment and our health. This impact level depends on emission control technology, incinerator design, and operation.

Lastly, plastics can be discarded and managed in sanitary landfills or left uncontained in open dumps or ecosystems (9).

Photo by Antoine GIRET on Unsplash

Photo by Antoine GIRET on Unsplash

A study from 2017 estimated the fate of all plastics ever made. This study revealed that of all produced plastic, 30% are in use. Of all plastic waste produced from 1950 to 2015:

Since plastic isn't biodegradable, exposure to sunlight weakens plastics, causing them to fragment into microplastic particles that can reach micrometer sizes. While research on the environmental impacts of these "microplastics" in marine and freshwater environments has intensified, their effects on terrestrial ecosystems remain poorly understood.

The exponential growth in plastics production over the past 65 years has outpaced that of any other manufactured material.

Without a well-designed management strategy for end-of-life plastics, humanity is conducting an uncontrolled global experiment: The accumulation of billions of metric tons of plastic across terrestrial and aquatic ecosystems. What will be the results of this experiment?

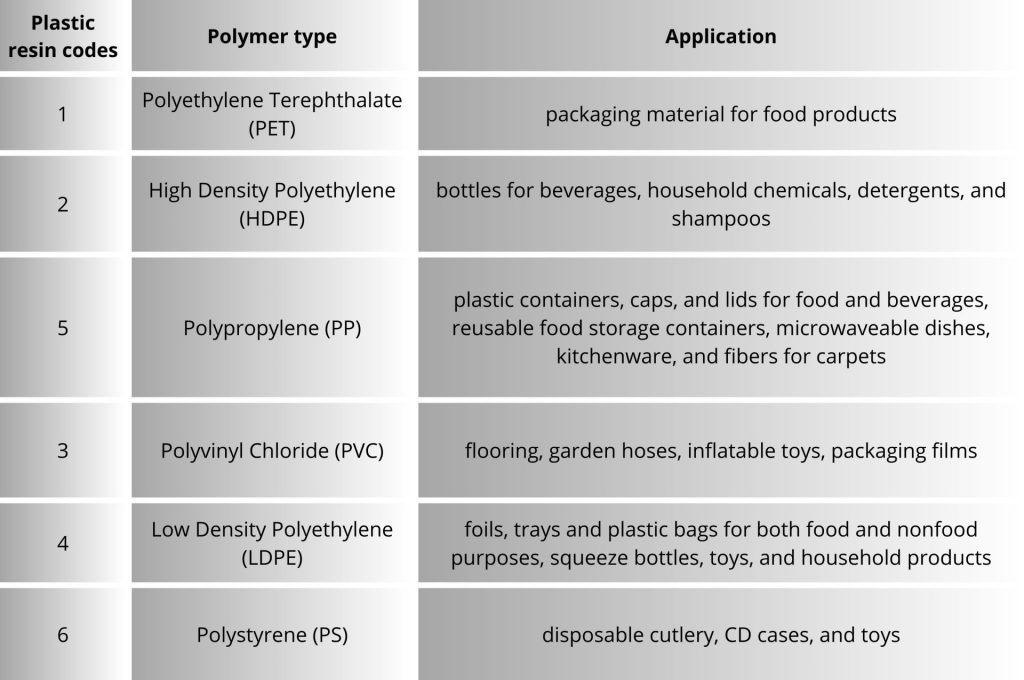

Plastic polymers are large molecules consisting of repeating units called monomers. There are different types of plastic polymers based on their chemical structure and properties. Some common types of plastic polymers include:

The most commonly recycled plastic polymers are PET (Plastic #1) and HDPE (Plastic #2). They are widely used in packaging for beverages, food, and household products, making them readily available in the recycling stream.

These plastics have established recycling infrastructures and strong market demand for recycled materials, making them economically viable to recycle. Due to their physical properties, it is easy to sort and process them at recycling facilities.

Plastic resin codes are symbols placed on plastic products to identify the type of resin used in their manufacturing. These codes range from #1 to #7 and help consumers and recyclers identify and sort plastics for recycling. The numbers also indicate the general ease (and thus, cost-effectiveness) of recycling, with 1 being the easiest and 6 and 7 being very difficult.

#1 - PET (Polyethylene Terephthalate)

#2 - HDPE (High-Density Polyethylene)

#3 - PVC (Polyvinyl Chloride)

#4 - LDPE (Low-Density Polyethylene)

#5 - PP (Polypropylene)

#6 - PS (Polystyrene)

#7 - Other

The term "100% recyclable" means that a product or material can be collected, processed, and remade into a new product without losing its quality or performance.

However, it's essential to note that while a product may be recyclable, its actual recyclability depends on the availability of recycling facilities and market demand for recycled materials. Additionally, products labeled as "100% recyclable" do not necessarily mean they are made from recycled materials, just that they can be recycled after use.

Photo by Ron Lach: https://www.pexels.com/photo/two-women-hanging-plastic-bags-on-the-clothesline-7827866/

Photo by Ron Lach: https://www.pexels.com/photo/two-women-hanging-plastic-bags-on-the-clothesline-7827866/

OK, so if plastic can only be recycled two or maybe three times, why do they claim on the bottles that it can be remade into a new product without losing its quality or performance?

When it comes to plastic the term "100% recyclable" can be a bit misleading. While a plastic product labeled as "100% recyclable" can technically be recycled, it doesn't necessarily mean that it can be recycled indefinitely without any loss of quality or performance.

Plastic materials degrade during the recycling process, meaning that each time they are recycled, their quality and properties degrade, limiting the number of times they can be recycled.

For example, a plastic bottle may be recycled into a lower-grade plastic product after its initial use as a bottle, such as plastic fibers for clothing.

Eventually, the plastic may reach a point where it can no longer be recycled due to contamination, degradation, or the lack of suitable recycling technologies.

Therefore, while a product may claim to be "100% recyclable," it's essential to understand that this term refers to the potential recyclability of the material, not necessarily its ability to be recycled multiple times without any loss of quality.

Photo by Nick Fewings on Unsplash

Photo by Nick Fewings on Unsplash

Mechanical recycling is a widely used method for recycling plastic waste, involving the following phases:

Mechanical recycling plays a vital role in moving towards a circular economy. Despite its economic and environmental advantages, mechanical recycling faces challenges. These include cost issues, degradation of mechanical properties during recycling, and variable quality of recycled products.

Moreover, the reprocessing of plastics can introduce degradation mechanisms that impact the quality and usability of the recycled material.

Chemical recycling offers a promising solution for dealing with non-recyclable, rejected, multi-layer, and contaminated plastic waste, in line with the principles of reduce, reuse, and recycle (10).

Chemical recycling technologies:

These technologies can address the global plastic pollution crisis and recover valuable materials. However, these methods face challenges like technological limitations, high capital costs, variability in feedstock, energy consumption, and inadequate regulatory frameworks.

Continued research and development are essential for progressing chemical recycling technologies and moving towards a circular economy.

A comprehensive approach that combines chemical recycling with waste reduction, reuse, and other waste management strategies is needed to tackle the plastic waste crisis and achieve a more sustainable future.

In conclusion, while recycling plays a role in managing plastic waste, it's crucial to recognize that recycling alone isn’t the ultimate solution to the plastic pollution crisis. The "100% recyclable" label on products can be misleading.

To make a difference, we should shift our mindset towards reducing plastic dependence, adopting reusable alternatives, minimizing single-use plastics, and advocating for sustainable practices.

By embracing sustainable living, we adopt practices that contribute to the well-being of the environment, society, and economy.

The idea of a sustainable diet was established in 2010.

A sustainable diet is considered to be a diet that resembles a nutritionally healthy diet.

Sustainability goes beyond admiration; it is a commitment to maintaining the delicate balance between our species and the planet.

Several scientists are “defending” meat consumption, replying that red meat is the source of essential nutrients.

Welcome to Sustainable Living by Science. With our scientific mindset, we are exploring how to nurture our well-being while caring for the environment. We are sharing the meaning of sustainability through evidence-based practices. Join us on this journey towards a greener, healthier future where science guides us to make the best choices for ourselves, the planet, and others.

All content is © 2024 by Sustainable Living by Science. All rights reserved.